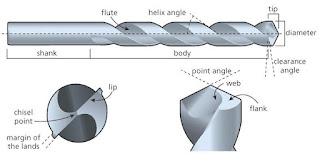

SUB MODULE 7.3: TWIST DRILLS

EASA PART 66 MODULE 7 MAINTENANCE PRACTICES SUB MODULE 7.3 Twist Drills: Twist drill is a cutting tool comprised of cutting point at tip of a shaft with helical cutting edge. While the range of tools, designed to create holes in metals and other materials is vast, the Morse-type (named after its inventor, an American engineer) of Twist Drill (refer to Fig. 3.13) is the one most commonly used in aircraft (and in general) engineering. The shank is the part of the twist drill that is gripped and driven by the chuck of the drilling machine and it is on the shank that the details of the type (grade) and diameter of the drill can usually be found printed or engraved. On drills up to 12.5 mm (½”) diameter, the shank is parallel and placed into the jaws of a self-centring chuck. On drills above 12.5 mm the shank is usually tapered (to a Morse Taper) of 1:20. The tapered shank fits directly into a matching tapered housing in the drilling machine spindle. The tapered shank usually ends in a tan...